Why use styrofoam presses

What are the challenges of handling Styrofoam?

Styrofoam and similar materials have excellent properties as packaging or insulating materials. Styrofoam consists of up to 98 percent air. Only two percent is polystyrene, a thermoplastic. This makes styrofoam inexpensive and versatile.

At the same time, these properties have unpleasant effects in the disposal. Styrofoam is voluminous and tends to break into small pieces. This causes pollution in the areas where styrofoam is processed or disposed of. At the same time, the large volume makes disposal and storage space-intensive. This results in high costs that are avoidable.

Which companies need polystyrene presses?

Styrofoam and related materials are found in a wide variety of areas. On the one hand, these materials are often waste products in production. On the other hand, they often serve as packaging and insulating materials. For this reason, a wide variety of companies process styrofoam, or the material is produced as a waste product.

Styrofoam is widely used in the fish trade, for example. Styrofoam is used to pack fish on trawlers due to its insulating properties and low weight. The same applies to central warehouses in the food sector. Repackaging generates packaging waste that is often styrofoam.

Large quantities of polystyrene packaging are also an everyday occurrence in furniture stores, electronics retailers and shopping centers. In addition, large quantities of styrofoam accumulate in recycling centers, collection points and recycling operations. All these companies need solutions for the effective and efficient disposal of styrofoam and materials with similar properties.

Manual processing of waste styrofoam is labor-intensive and does not achieve the desired results. The material cannot be compressed and creates small pieces of styrofoam when crushed, which in turn quickly contaminates the environment as they are very difficult to remove. Intermediate storage additionally takes up a lot of space.

For this reason, such companies need efficient, space-saving and inexpensive solutions for the its disposal. A styrofoam press is the right answer for economical and practical disposal.

What materials do polystyrene presses process?

The advantage of the presses is that they can handle a wide range of materials multifunctionally. They thus process a wide variety of transport and protective packaging as well as packaging or thermal insulation material made of this material. In the field of styrofoam, there is a wide range of different material mixtures, either hard or soft according to the area of application and are available on the market in various forms.

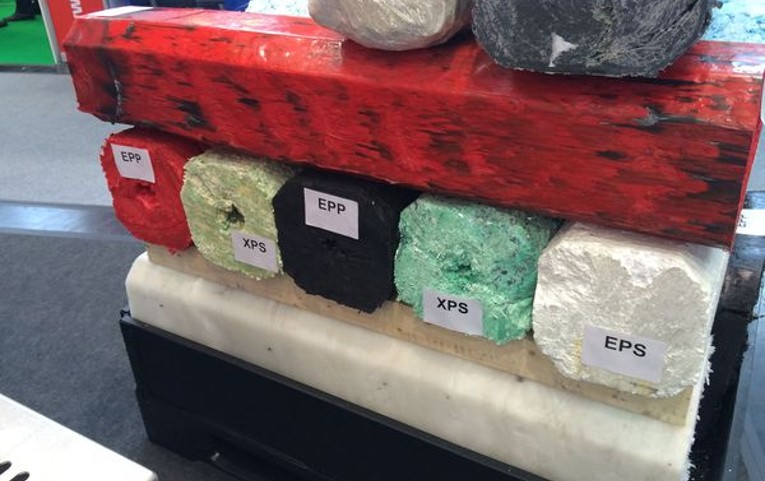

For example, EPE is used as a packaging material in many areas such as electronics. The construction industry and trades use XPS foam for insulation boards. PUR insulating materials are used as insulating material in roofs and basements. Styrofoam presses process all forms of these plastic-based materials. Styrofoam presses can handle the following types of material:

- expanded polystyrene, styrofoam (EPS)

- extruded rigid polystyrene foam (XPS)

- expanded polypropylene and particle foam (EPP)

- expanded polyethylene (EPE)

- polyurethane (PUR)

The solutions for styrofoam disposal from Hunkeler Systeme AG

We at Hunkeler Systeme AG offer different solutions for the disposal of styrofoam and similar materials. You can create systems that are optimally tailored to your needs. These system solutions consist of the following three components:

- shredder for Styrofoam

- compactor for EPS, XPS and EPP

Styrofoam shredders help with the processing of unwieldy formats

Styrofoam often comes in large sheets or molded parts. This makes disposal difficult. With styrofoam shredders we provide you with a simple and effective machine for solving this problem.

The shredders process EPS, XPS, EPS and PUR rigid foam. The machine processes these materials into small pieces. From there, they are directly filled into bags. In this way, uniformly sized and easy-to-use bags of residual polystyrene waste are produced. Due to the direct fill method, contamination of the environment is excluded.

With the styrofoam shredders, a volume reduction by a factor of three is possible. This and the uniform size of the bags simplify disposal. Handling and transport costs are thus reduced. Styrofoam shredders from Hunkeler Systeme AG are compact, inexpensive and mobile.

Compressors from Hunkeler Systeme AG for different types of styrofoam

The compressors allow the actual pressing of the polystyrene waste. We offer systems that are versatile in handling different types of styrofoam and plastic. The styrofoam compactors are characterized by robustness, high performance and efficiency.

One of the strengths of our styrofoam presses is the enormous volume reduction. With our presses, you can achieve a compression of up to 1:50, saving you a lot of space and money in storage, removal as well as disposal.

With our polystyrene presses you can process EPS, XPS, EPP or EPE. The presses transform even very fine and loose material into dimensionally stable blocks. Re-expansion is impossible. The polystyrene bales do not lose any flakes and therefore do not generate any contamination.

The output bales always have the same shape. This is another advantage of using a styrofoam compactor. This results in stackable blocks, a clear advantage during storage and transport. Space-saving handling is thus possible, which further reduces the costs of processing polystyrene residues.

What are the advantages of polystyrene presses from Hunkeler Systeme AG?

Our polystyrene presses offer you many useful features in practice. For example, the systems are designed for continuous operation. In this way, you process even large quantities of accumulated polystyrene waste.

During the pressing process, the machines use innovative technology. External heat supply is no longer necessary. Instead, the system generates the necessary heat for the pressing process on its own. The heat energy is generated by the friction of the material in the screw conveyor.

In combination with the low torque of the screw conveyor, this ensures very energy-efficient operation of the styrofoam presses. This reduces running costs and makes the system particularly economical.

In addition, the machines are very easy to operate. Another advantage is the compact dimensions. This means that integration into existing plants is usually possible without difficulty. These are the advantages of the polystyrene presses from Hunkeler Systeme AG at a glance:

- high reduction of the volume

- ow energy consumption due to innovative technology

- robust and durable presses

- user-friendly machines

- intelligent and individual system solutions

- reduction of transport and disposal costs

Solutions for bulky EPS waste

Often, styrofoam residual waste is large, chunky pieces. This is the case, for example, with packaging material. We at Hunkeler Systeme AG have prepared THE TIGER system as a solution for this.

Before the actual pressing process begins, a pre-crusher processes the chunky polystyrene parts. Thus, the styrofoam components have a maximum size of 50 millimeters when they enter the press. This ensures uniform, dimensionally stable blocks.

The system is available in several sizes, meaning between ten and 1000kilos of material can be processed per hour. The density achieved is 350 kilograms per cubic meter.

The all-rounder: The LION polystyrene compactor

The LION system is designed to handle a wide variety of styrofoam types. You can press EPS, XPS, EPP and also EPE with this machine. There are 20 different programs available so that you can adapt the press to the respective application.

The LION polystyrene press achieves particularly high densities of up to 700 kilograms per cubic meter. Hourly outputs of up to 500 kilograms are possible with the largest variants of the system. At the same time, the press operates automatically and thus without the need for personnel. This increases cost-effectiveness by automating processes.

The advantages of EPS compaction

Especially the compaction of EPS with polystyrene presses is interesting in practice. EPS styrofoam is a material that is not biodegradable. Accordingly, there are currently only two options. In addition to disposal, there is recycling.

Disposal is an expensive process – especially if the material does not arrive at the disposal company in compressed form. Disposal companies are also reluctant to work with material that is expanded and brittle, potentially contaminating the environment with small particles.

Therefore, blocks that are already compressed in the disposal process offer significant advantages. They save capacity in handling and transportation. For disposal companies that charge by volume, you can reduce costs by up to a factor of 50 thanks to the high compression rate.

Another option is to send the EPS bales for recycling. Under certain conditions, recycling EPS is possible and the material is suitable for recycling. For this, the EPS must be available as a dry, uniform and unmixed bale.

With our styrofoam presses you produce exactly such bales. In this way, it is possible to turn formerly problematic styrofoam residues into valuable raw materials for the recycling industry. Residual waste that used to be disposed of expensively can be turned into a source of income. At the same time, this is an important factor for an environmentally friendly orientation of your company.

The advantages of styrofoam presses in preparation for transport

In many cases, it is necessary to transport the polystyrene residues, either within the plant or when it is delivered to a recycling company. Haulage companies are expensive, and billing is by volume.

This is where the problems of handling non-compacted styrofoam become apparent. A standard container or truck is capable of carrying about 800 kilograms of loose EPS. The Styrofoam is so voluminous that the entire storage space is occupied.

If, on the other hand, you use polystyrene presses beforehand and reduce the volume, a container can load up to 24 tons of EPS briquettes. This reduces transport costs by a factor of 30 in the best case, while loading is also much easier.

Individual solutions for the disposal of polystyrene from Hunkeler Systeme AG

We not only sell polystyrene presses, but also plan your plant on request. As a specialist in disposal technology, we take individual wishes and requirements into account.

Our team therefore advises you in all phases of your project. This starts with a comprehensive consultation followed by a needs-analysis, and then our engineers plan a suitable plant. 3D visualization is used in the process. We design the systems to meet your capacity requirements.

Individual engineering of the machines is just as much part of our service as support during assembly. In this way, you receive polystyrene presses that are perfectly designed to meet your structural and economic requirements. Of course, service and maintenance of the presses are also part of our services.

Are you looking for intelligent and, above all, efficient solutions for processing polystyrene residues? Then contact us today. Together we will find an optimal solution for your operation.