The positive effects of dust extraction for your company

Dust and dust deposits in industrial environments are problematic. Dust not only pollutes the air we breathe. It can also damage machines and have a negative impact on product quality. Automatic dust extraction systems are the solution for this challenge.

What problems does dust extraction solve?

Especially in the packaging industry, dust often occurs during the manufacturing processes. For example, large quantities of dust are released during the production and processing of corrugated cardboard. This has negative effects like:

- Reduced product quality

- Health risks for employees

- Increased cleaning effort for buildings and systems

- Higher failure rates and wear on production machines

Dust adhering to surfaces can reduce the quality of the finished packaging. Defective products, poor processing quality or dust contamination are the consequences. If the dust settles in the production machines, they wear out more quickly. Costly repairs and even the failure of entire production lines can be the result.

Last but not least, dust also poses a health risk to employees in factories. In the form of fine dust, it can spread in work rooms and halls and be inhaled there. The consequences of increased exposure to dust are mainly lung diseases.

What dedusting solutions are available?

Hunkeler Systeme AG has been developing dedusting systems tailored to the needs of companies in the packaging, logistics and paper industries for a long time.

One of our most popular solutions in this area is the iPEM, a paper web dedusting module for digital printing lines. It removes dust particles from the paper webs and thus helps to keep the printer and other machines dust-free. Waste caused by soiled paper, poor print quality and production downtime due to cleaning work can thus be reduced to a minimum.

With our compact Hunkeler Kompakt Aircleaner HKA, you can efficiently reduce the amount of free-floating fine dust particles in large rooms and halls. In addition to its use in production environments, the HKA devices are also suitable for use in warehouses and logistics buildings and prevent dust from settling on stored products and contaminating them. The ISO 16890-certified devices also reliably filter bacteria, viruses and pollen from the air. The result is a much healthier indoor climate that also meets the requirements of the Health and Safety standards.

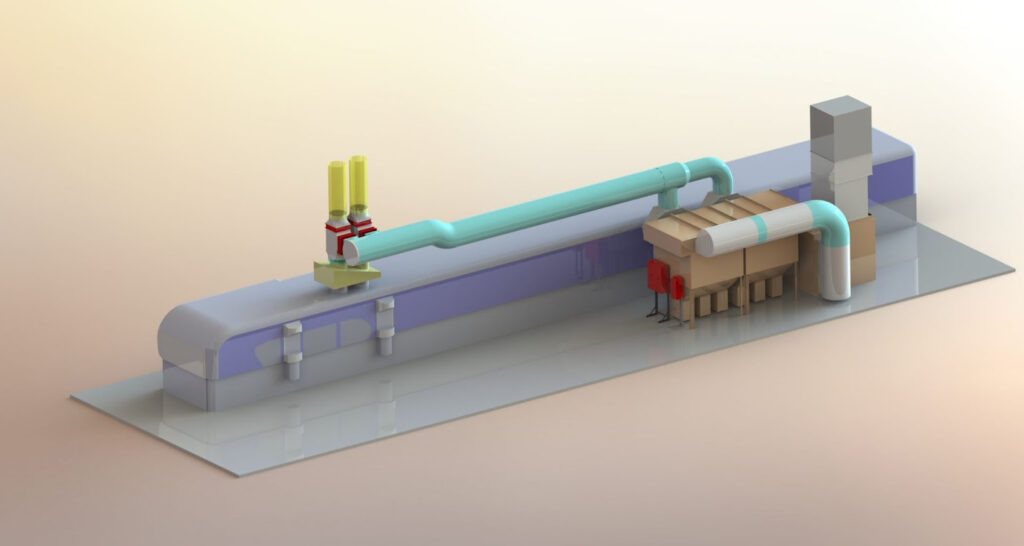

Our solutions for dedusting production machines capture the dust directly where it is generated in the production process. This means that the dust does not even leave the area where it is generated. This significantly reduces the cleaning effort in the production area and improves the air quality at the same time. Other benefits include reduced wear, increased service life of the systems and improved reliability. At the same time, the quality of the end product is improved. Dust extraction systems can be integrated directly into the production process and are suitable for both indoor and outdoor installation.

Do you have further questions about dedusting in an industrial environment? Are you specifically interested in one of our solutions? Then get in touch with us! We will be happy to help you!