How stripping waste shredders increase the productivity of your flatbed die-cutter

Flatbed die-cutters of size 106 and 145 are still indispensable in the production of folding cartons, displays and other advertising materials made of cardboard. Improving the efficiency and productivity of such machines is possible, among other things, by optimizing the waste extraction. The SAZ stripping waste shredder from Hunkeler can help with this. In the following article, you will learn more about the advantages of the technology.

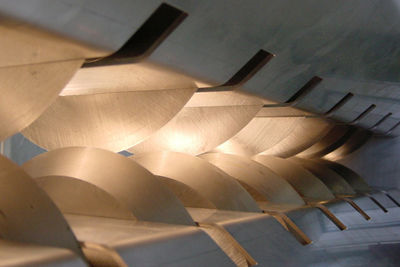

What is the function of the SAZ stripping waste shredder?

The SAZ stripping waste shredder is installed directly in the stripping station of a flatbed die-cutting machine. The large-area die-cutting waste then falls continuously into the feed chute of the shredder. There they are shredded to a size of around 30 by 250 millimeters in the shortest possible time. Only after shredding are they collected by funnel and extracted.

Due to the optimal size of the stripping waste after shredding, extraction systems can be down-sized. As a result, significantly less air needs to be drawn in and conveyed by the system. Power and energy savings for the extraction system are the direct result. The optimal size of the waste also reduces the likelihood of clogging in the piping of extraction systems, which can cause a production stop.

The SAZ stripping waste shredders from Hunkeler Systeme can be used flexibly. The feed chute can be individually adapted to flatbed die-cutters of sizes 106 and 145. The stripping waste shredder also has all the necessary electrical and mechanical interfaces to be integrated directly into an extraction system. Equipped with rollers, the SAZ stripping waste shredder is also mobile and can be moved easily. This simplifies accessibility to the stripping station, for example, in order to carry out maintenance or reconfigurations on the die-cutting machine.

These are the advantages of our punching waste shredders at a glance:

- Energy savings of the extraction system

- Efficient utilization of flatbed die-cutting machines

- Flexible application

- Mechanical and electrical standard interfaces to die-cutting machines and extraction systems

- Low-maintenance and durable cutting unit

By the way, an ideal complement to the stripping waste shredder is the SZM matrix shredder from Hunkeler Systeme.

How much energy can be saved with a stripping waste shredder SAZ?

In principle, of course, this depends heavily on the conditions on site. Typically, however, it is possible to reduce the air volume required to extract the waste by up to 60 percent per die-cutting machine by using stripping waste and matrix shredders. This is accompanied by a reduction of about 50 percent in the energy required for the extraction system. With a typical plant and an electricity price of 0.25 CHF/kWH, this can mean a cost reduction of 20,000 Swiss francs per year. This calculation is based on a size 106 flatbed die cutting machine running in 24/5 operation.

Do you need an individual forecast of your energy savings or do you have further questions about our stripping waste shredders? Then please feel free to contact us. Our team can be reached by phone and e-mail at any time.