Pressing recyclable materials: Vertically form cardboard, paper or foil into bales

Whether in industry or retail, cardboard packaging and films are among the materials that accumulate every day. For example, they represent waste products in production or come in the form of packaging material. In any case, companies need practical disposal solutions. Here, the use of cardboard and film presses with vertical technology is the ideal solution. These systems have the right properties for pressing recyclable materials.

How do vertical presses work?

Vertical balers are a type of baling press. This type of baler is mainly used to compress packaging material such as cardboard or film. The press produces the finished compressed material in the form of bales, which are easy to transport and can be stored in a space-saving manner.

Vertical balers combine the baler, the feeding chamber and the output of the finished bales in one compact system. The pressing process takes place vertically, so the actual baler is located above the recyclables being pressed. This design makes vertical balers particularly space-saving solutions.

What machines are available that vertically press recyclables?

The machines for vertical pressing of recyclables differ mainly in size and, additionally for different materials. With some presses you have the option of selecting the material to be pressed via the settings.

A particularly compact model, such as our V-Press 503, only requires a surface area of 95 x 68 cm. Operation is possible with a standard household 230-volt power connection. This solution is therefore ideal for retail outlets and areas where space is at a premium. Nevertheless, the system has a powerful pressing force of 30 kN.

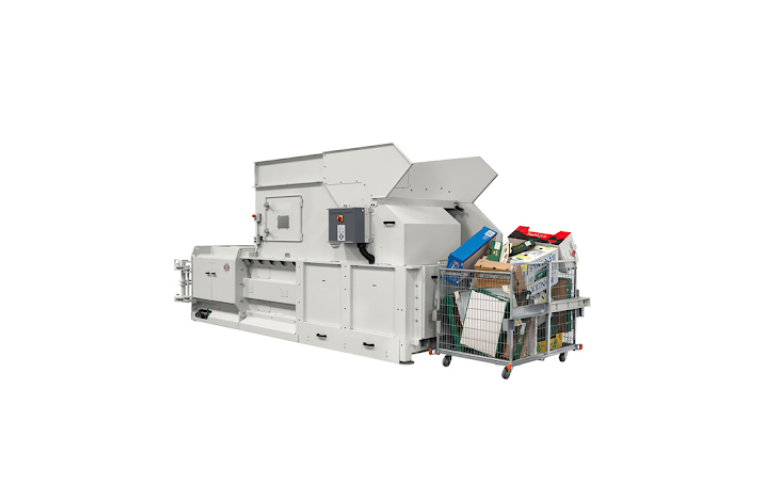

Larger solutions like the V-Press 860 TimeSave are at the other end of the spectrum. This system features automatic filling. The machine picks up collection carts and tips them into the press independently. This simplifies and speeds up filling considerably. The finished bales are wrapped by the machine with Quicklink wire.

Bales of different size

The various vertical balers produce bales of different sizes. The compact systems produce bales with a side length of 70 x 50 cm. In the large presses, the weight per bale is up to 550 kilograms. These bales have dimensions of 120 x 78 x 120 cm.

The weight and size of the bales also depends on the material to be processed. Vertical presses handle various recyclable materials that are produced daily in trade, commerce and industry. The V-Press series from Hunkeler Systeme AG also has a control system that allows you to select which material you want to press. Thus, you are flexible and can press different recyclables with one system.

Vertical presses are therefore well suited for retail. These days, supermarkets and other retailers are increasingly obliged to take back packaging material. With a compact press, you provide a multifunctional system for disposal. It takes over the compression of a large part of the packaging materials that arise.

Hunkeler’s vertical presses can process the following recyclables:

- cardboard boxes

- paper

- slides

- hard plastics

- PET bottles

The different door variants of the vertical presses of Hunkeler Systeme AG

With the V-Series from Hunkeler Systeme AG, you have several door variants to choose from. This allows you to select the right system for your own situation. The following options are available to you:

- double door

- press with filling flap

- sliding door

The vertical presses equipped with a double door provide easy access to the press. They are mainly found in vertical carton presses, because these packages are often bulky and unwieldy.

The vertical presses with a filling flap have doors that open downwards. Film presses in particular benefit from this variant, as you can simultaneously use the door as a deposit surface for small materials. After closing the filling flap, the pressing process starts automatically.

The vertical presses with a sliding door are particularly space-saving. Here, the door is simply pushed down and thus does not require any additional space when opening. This variant provides easy access to the press and facilitates the filling of bulky cardboard boxes.

There are also several options for door closures. The closures are based on the size and pressing power of the machines. You will find toggle door latches on the smaller systems of up to 40 kN pressing force. A handwheel door latch allows quick and easy access. The hydraulic door closures are mainly used on the large machines and operate automatically.

What are the advantages of vertical presses when pressing recyclables?

Vertical presses have many specific features that are advantageous for you in practice. The most interesting aspect is the space-saving design. Thus, vertical systems are the most compact solution for the pressing of recyclables.

At the same time, the presses work very effectively. Pressing reduces the volume of cardboard boxes by a factor of 20. This way, voluminous packaging material is prepared for disposal and space is storage space is minimised at the same time. The bale shape allows for orderly intermediate storage. Overall, this reduces the space required by up to 95 percent.

The unmixed residual waste is also a valuable raw material. You can pass these valuable materials on to recycling and thus return residual waste to the raw materials cycle. In this way, you also avoid costs for waste disposal and protect the environment at the same time.

Vertical presses are particularly economical in operation. The presses only operate when you are feeding material. Thus, cardboard and film presses are good solutions when material accumulates on an irregular basis.

Manual filling via the large doors is also an advantage of the vertical presses. This allows bulky cartons to be input directly without time-consuming preparation. Vertical balers are also user-friendly; both the filling and removal of the bales is ergonomically designed. The presses with sliding door operate automatically and eject the pressed bale by themselves as well.

Vertical presses are also cost-effective solutions for pressing recyclable materials. At the same time, the presses help to reduce disposal costs and save space in the warehouse. This means that the plastic and cardboard presses have an attractive price/performance ratio and are very profitable in practice.

These are the key advantages of vertical presses:

- flexible in application

- space-saving installation

- user-friendly

- energy efficient and quiet

- cost-efficient solution for the pressing of recyclable materials

Vertical carton presses and other systems from Hunkeler Systeme AG

With the V series, we offer you versatile presses with a wide range of applications. These vertical presses are optimized for space-saving compression of recyclables such as cardboard or plastic. The different models in the series allow you to choose a system that fits your requirements.

With the Hunkeler V-Series, you also benefit from the Torsion Control System (TCS). It controls the inclination of the bale plate and prevents imbalance during baling caused by uneven loading. This always results in symmetrical bales, and the baler is protected from damage caused by uneven baling pressure. This ensures a long service life for the vertical balers.

In addition to new equipment, we also offer used and demonstration machines, such as used vertical cardboard presses. A used carton press is a favourable option to press recyclable materials efficiently. Your logistics and merchandise management will benefit from such a solution in any case. Furthermore, we at Hunkeler Systeme AG design customized concepts for our customers. Do you need an individual solution for the pressing of recyclables? Then please contact us directly and let us know your requirements. Together we will find the right press for your company.