Conveying and sorting technology: These are the application areas & challenges

Modern sorting and conveying technology helps automate and replace manual work. Properly integrated, the technology helps you build efficient and space-saving systems. Learn more about the versatile applications and advantages of conveyor technology.

What are the different options offered by conveyor technology?

Modern conveyor technology is versatile and flexible. The different variants adapt to your requirements. In this way, disposal systems are created that exactly fit the existing conditions in each case.

Such technology has an important task in disposal systems. It handles the semi-automatic or fully automatic transport of residual waste between two points. This can be from the point of origin to further processing or disposal. Conveyor technology is also used for receiving residual waste. From there, the solutions transport the waste to the respective stations.

We at Hunkeler Systeme offer you the following solutions in the field of conveying and sorting technology:

- feeding systems

- conveyor belts

- tilting devices

- pneumatic conveying systems

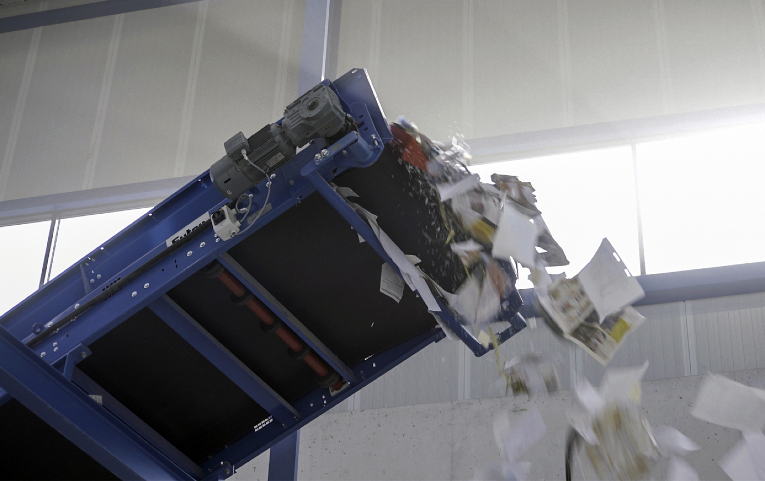

Conveyor belts – versatile transport systems for small and large materials

Conveyor belts are the all-rounders in waste disposal technology. A wide variety of materials can be moved between two points via these load-bearing belts. For example, they connect production machines with presses.

In addition, conveyor belts are important components in sorting technology. They transport waste during sorting and also perform the task of transporting the separated raw materials or residual waste to the next point in the sorting system.

There are belt conveyors and chain conveyors. Chain conveyors are mainly used to transport piece goods, such as pallets or even goods carriers. Belt conveyors are suitable for residual waste with different weights and dimensions.

Pneumatic systems for the transport of waste

Pneumatic conveying systems are especially interesting for the task of waste disposal in industrial production. This technology works with compressed air, fans and negative pressure. Thus, the pneumatic conveyance of waste is possible with our systems.

The advantage of pneumatic systems is their ability to transport production waste, dust-free, in closed and compact pipes. In this way, you intercept residual waste directly at the point of origin and transport it safely as well as separately for disposal.

We at Hunkeler Systeme have invested a lot of development work in the controls for these pneumatic systems. In this way, we achieve high energy efficiency. The automatic shutdown ensures that the system is de-activated when no waste is being transported. The fans are then in energy-saving standby.

Tipping devices as a practical and inexpensive solution for waste disposal

Conveying and sorting technology also includes numerous variants for the tipping devices. These are available for containers and bins of different sizes and types. A press hydraulic system tilts the container and thus transfers the waste to the next process stage.

We at Hunkeler Systeme offer tipping devices that are low-maintenance and robust. For example, our solutions feature greasing nipples for continuous lubrication of moving parts. Included in the range are tilting devices designed for continuous operation.

These tipping devices can be installed both on ramps and directly on the ground. The systems are compatible with DIN EN 840 containers as well as other standard containers. You can combine such a tipping device with a press container or a stationary press, for example. This creates a low-maintenance and cost-effective disposal device that generates little manual work.

Feeding systems from Hunkeler Systeme – compact and efficient special system

Our Hunkeler Compact Buffer is designed for very special tasks. Namely, the HCB 600 is designed for the transport of banknotes. The special feature is that the system works fully automatically. As if that were not enough, the banknotes are protected from access during transport. Directly connected to the system is a shredder that safely destroys the banknotes.

In this way, the HCB 600 loading system meets the stringent requirements that are necessary and prescribed for handling cash. Another advantage of the system is its extremely small space requirement and very high security.

What materials can be transported with conveyor technology?

The conveying and sorting technology is adaptable and therefore suitable for a wide range of materials. The different systems are each optimized for specific types of waste. This is why choosing the right conveyor system for the job is so important.

Pneumatic conveying systems are particularly suitable for small wastes generated in production. This can be scraps of paper or cardboard or even plastic waste, which can also come from a shredding system.

The conveyors are suitable for very different materials, depending on the design. This can be smaller metal scrap, PET and similar waste. Conveyor belts also handle unevenly shaped materials without difficulty. As chain conveyors, the belts also transport larger unit loads, such as containers, pallets or goods carriers.

Tilt conveyors are the all-rounders. They can handle all materials that you collect in containers or boxes. Whether small materials such as Styrofoam and plastic or bulky waste, car tires and wood – tipping systems handle all these types of waste.

An overview of the materials and containers you can transport with conveyor technology from Hunkeler Systeme:

- paper

- newspaper waste

- cardboard packaging

- PET

- plastics

- metal waste

- polystyrene

- wood

- banknotes

- pallets

- goods carriers

- containers

- boxes

Conveying and sorting technology in industry and production

The industry expects very specific services from conveying and sorting technology. The main focus here is on automation and the safe and rapid removal of materials. Energy efficiency and cleanliness are also important issues.

The various solutions enable all these requirements to be met. Pneumatic systems provide a direct link between the production site and waste disposal. In combination with other systems for waste disposal, this creates an automatic system for transport and disposal.

Suitable for this purpose are, for example, extraction systems and presses or containers: Waste generated during production is transported directly to the desired destination via the conveyor system. In this way, no pollution occurs at the production site or anywhere else in the factory.

The conveyor system transports the waste directly from the factory floor if desired. For example, a container can be placed there. In this way, valuable space within the production facility is available for other tasks.

Sorting plants – an important point on the way to automated disposal

Automated disposal of recycled material and residual waste is only possible with the help of a sorting plant. Modern sorting technology is capable of separating different types of residual materials cleanly and efficiently. Various techniques are used in the process.

Paper and cardboard are important raw materials. These days, such materials can be recycled effectively and to a high degree. This is good for the environment and at the same time you collect valuable raw materials. Clean sorting is the basis for a high degree of recycling and a circular economy.

Our sorting plants contribute to this environmentally friendly recycling. They are based on a multi-stage sorting line. In these stages, the sorting plant removes foreign materials and sorts the paper waste. The plant automatically transports the respective materials to the desired points. This is done with the help of belts and other technology. Sorting systems thus also require conveyor technology in order to operate fully automatically.

The various sorting stages consist of screens, air classifiers or separators, among other things. NIR spectroscopy is also used in sorting. Here, infrared sensors detect what type of material is on the conveyor belt. Each individual piece is checked. The system registers the type of material and sorts out unwanted materials. Compressed air nozzles are used to selectively remove the foreign materials.

Sorting systems are also available for materials other than paper or cardboard. At Hunkeler Systeme, we provide sorting technology for foils, PET, cardboard and similar recyclables. Some of the benefits of using automated sorting technology include:

- reduction of waste

- separation of mixed waste by type

- high degree of recycling

- reduced energy consumption

- minimization of manual labor

- reduction of the need for virgin material

What role does sorting and conveying technology play in waste disposal?

Conveyor technology is now an integral feature in recycling companies and waste management in general. Above all, it ensures order and effectively reduces the need for manual labor. Waste management companies which successfully utilize such technology work both economically and efficiently.

The various solutions thus also optimize everyday life in the recycling plant. Tipping devices, for example, can be combined with press containers. This also ensures convenient filling. Conveyor belts take residual waste from reception to sorting and finally to disposal.

Conveying and sorting technology from Hunkeler Systeme – innovative and efficient

At Hunkeler Systeme, we focus on well thought-out overall systems. For this reason, on the one hand, we supply all components for intelligent disposal solutions in industry and waste management. In addition, we also take over the conception and planning of such systems. In this way, you receive all services reliably from a single source.

At Hunkeler Systeme, we continue to attach enormous importance to intelligent waste management for a green future. We achieve this through optimized control systems, which save energy and reduce costs.

In our portfolio, you will find the entire range of conveying and sorting technology. This includes solutions based on conveyor belts, pneumatic systems and tipping devices. In total, we have over 80 years of experience in the field of waste disposal technology.

Practical examples – how conveying and sorting technology from Hunkeler Systeme optimizes daily life

Our technology is used by many companies, including large industrial companies as well as recycling companies with high demands.

A practical example is the Coop distribution center in Schafisheim. Here, in addition to 100 tons of PET bottles, the company also processes plastic foils, PE hollow bodies, wood, cardboard, refuse and organic waste every day. The task was to create a disposal system that would compact the residual waste as much as possible. In addition, there was to be a separation between recyclable materials and waste for incineration.

Conveying and sorting technology plays a central role in these tasks. We at Hunkeler Systeme designed several conveyor belts, each 106 meters long. These supply the balers with residual waste. In addition, the waste is transported directly to the truck loading ramps, where it is baled and immediately removed. The result is an automatic and efficient system.

The largest waste paper sorting plant in Switzerland also relies on conveyor technology from Hunkeler Systeme. Here, reliable sorting and conveyor technology are indispensable. Every year, Alpabern AG in Bern-Wankdorf processes around 70,000 tons of recyclable materials. Most of this is waste paper, but it is contaminated with other materials, such as plastic or glass.

For this reason, reliable separation is necessary. Given the volume of material, the focus is on reliable, high-capacity systems that operate autonomously. Among other things, near-infrared sorting modules, ballistic separators and ascending belts are used. We have integrated these into a multi-stage sorting system. The plant ejects up to 60 bales of pure recycling material per hour for further processing in the paper industry.

Trucks are also loaded automatically using conveyor technology designed by Hunkeler Systeme. Thus, the system works fully automatically and reliably from delivery to sorting and dispatch.

Your own solution – individually planned and designed with Hunkeler Systems

Adapted solutions are usually required when setting up disposal systems. Not only the type of waste, but also the structural conditions and the existing production machines set the specifications. Only too often, space is also limited. Therefore, we always look for individual and clever solutions, which may possibly look like this:

- shaft installation

- installation under the ceiling

- pit installation

- installation below the production machines

In addition, the overall concept determines the functionality in everyday life. The focus here is on reliability and practicality. We achieve this by using high-quality equipment and materials as well as the precise planning of the dimensions. Clean transitions, seals and control systems for the belt run are also important. This is how we at Hunkeler Systeme realize reliable conveying and sorting technology with trouble-free operation.

If you are looking for an experienced and competent partner, we at Hunkeler Systeme are your partners. You can contact us at any time if you have questions or are planning a project. We will support and advise you expertly and without obligation.