What Are Suction Systems?

Suction systems are an effective solution for the disposal of waste products in manufacturing. However, these systems have even more functions than the mere disposal of residues.

For example, these systems clean the air at the same time. You can also use them for separating and extracting material. For this reason, they are also referred to as extraction systems. In the following, you will learn more about their mode of operation as well as Hunkeler Systeme AG’s suction systems.

How is waste transported within a suction system?

One of the central tasks of suction and filter systems is the transport of residual substances. The systems remove unwanted substances directly at the source. This can be from the production or the packaging area.

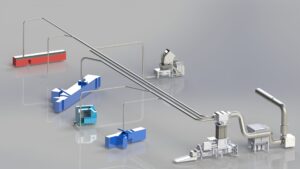

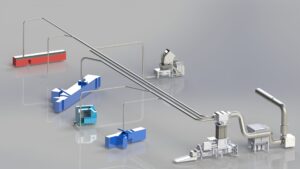

There are various technical solutions for this. Suction and filter systems with negative pressure or with pneumatic conveying are mainly used. With this technology, it is possible to extract highly effective waste products directly at the point of origin. The functional principle of Hunkeler’s suction and filter units is explained in this video.

This solution shows its advantages, particularly with dust and small particles. Thus, suction systems prevent polluted air from escaping from the unit. At the same time, the systems remove dust and similar material before they contaminate the air and the production areas.

The system transports the particles via the vacuum in the duct network. On the one hand, the negative pressure results in a very high transport speed. On the other hand, this allows particularly compact systems to be implemented.

What are the advantages of a suction system compared to other solutions?

Various solutions are suitable for the disposal of residual materials in production. For example, a belt system is often used. However, it has significant limitations and disadvantages compared to a suction system.

Belt systems perform particularly well in terms of engergy-costs. On the other hand, suction systems are more space-saving, more flexible, and improve production performance. The central advantages of a suction system are:

- Space-saving due to ceiling mounting.

- Thanks to the duct system, space in the production area is freed up for machines.

- Direct extraction of dust at the source improves air and product quality.

- A highly flexible solution that can be retrofitted with little effort.

- Improvement of the performance of the production equipment.

- The reduction of personnel requirements for waste disposal.

You can find out more about the advantages of a suction system in our article on the subject.

Are suctions systems economical?

In a setting where rising energy costs require companies to think sustainably, modern suctions systems can actually reduce energy consumption. In particular, suction systems from Hunkeler Systeme AG offer energy-saving smart controls. These features make it possible to run a system only at the necessary load.

In this case, there’s the potential for savings of up to 60% by regulating the output of the suction system. This workload includes fan usage, among other mechanisms. Not only does it reduce operating costs, but it also reduces wear on the system. This translates to reductions in equipment service costs and the extended lifespan of the system.

Residual heat can also be utilised with certain suctions systems. Filtered air that is not exhausted from the building can be circulated to reduce heating costs. This is especially effective in colder seasons, further optimising energy consumption.

Lower operating costs aren’t the only advantage a suction system can afford your company. There’s also an environmental benefit to choosing an energy-efficient solution. With the right system, you can effectively reduce your ecological footprint and feed collected waste into the recyclable materials cycle.

A suction system for your company

Are you looking for an effective and efficient suction and filter system for your company? Hunkeler offers a wide range of compact extraction and filter units. We also design individual solutions to adapt the system to your needs.

Please use our contact form to ask any further questions and let us know your ideas and requirements. We will contact you promptly and provide you with expert advice.