EPS presses for maximum material compression

Styrofoam is one of the most common packaging and insulation materials. The material is lightweight, inexpensive and resource-saving due to its high air content. However, disposal is often only possible under difficult conditions. An EPS press is the solution. Such a polystyrene press compresses the material to a minimum.

Which companies benefit from an EPS press?

An EPS press is useful in any area where larger quantities of polystyrene are produced. The smaller presses are a useful addition, especially in the trade. Our larger systems are designed for companies where higher quantities of EPS have to be disposed of on an ongoing basis. Some examples of useful applications are:

- retail

- food retailer

- central warehouse in the food sector

- fish processing industry

- recycling centers and collection points for residual waste

- as a central disposal solution in shopping centers

- furniture dealers

- electronics retailers

For which materials is an EPS press suitable?

EPS presses are primarily designed for expanded polystyrene, i.e. Styropor. In addition, Hunkeler Systeme AG presses also process other similar materials. These include:

- polyurethane (PUR)

- extruded rigid polystyrene foam (XPS)

- expanded polyethylene (EPE)

- expanded polypropylene and particle foam (EPP)

Thus, our EPS presses are versatile systems for the compression of polystyrene-based packaging materials.

The advantages of EPS press

The key advantage of an EPS press is the space it saves on disposal. EPS consists of 98 percent air. A press compresses the material by a factor of 50, thus conveniently preparing the bulky packaging material for further use and allowing it to be temporarily stored in a space-saving manner.

An interesting aspect of EPS is that the material is 100 percent recyclable. The recycling of polystyrene has increased significantly in recent years. There are now recycling companies that specialize in EPS. Pressed residual waste then becomes a valuable raw material with a new and useful purpose.

The uniform ingots that exit the EPS press can also be optimally stacked and transported. This facilitates disposal or sale as raw material to recycling companies.

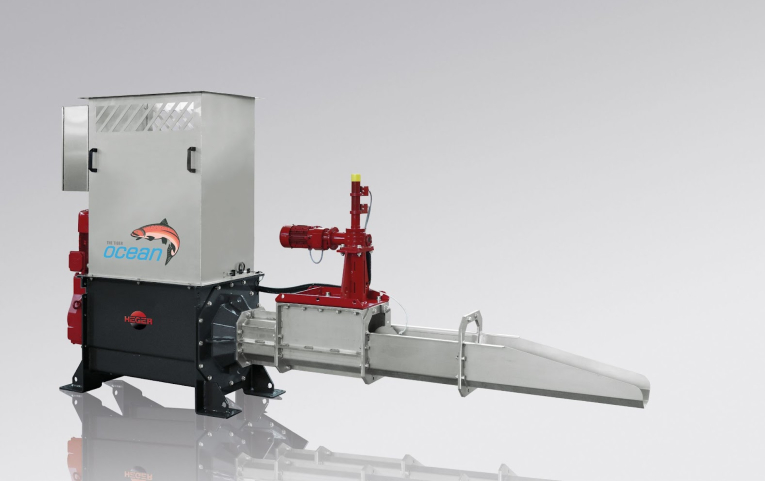

EPS presses from Hunkeler Systeme AG

We offer a wide range of EPS presses for various applications. Our range also includes compressors for EPS, XPS and EPP in different sizes.

Are you looking for an individual solution for disposal? Use our contact form and tell us your requirements. Together we will find a practical solution for your business.